Previously known as ns4 grade 5251 has many similar attributes to grade 1050 aluminium sheet and is probably the 2 nd most popular grade of aluminium sheet used in the uk today.

How to tell grade of aluminum sheet.

It can be manufactured using common methods and it has excellent workability in the annealed condition.

It may be drawn or formed into intricate shapes and its slightly greater strength in the annealed condition minimizes tearing that occurs in 1100 and 3003.

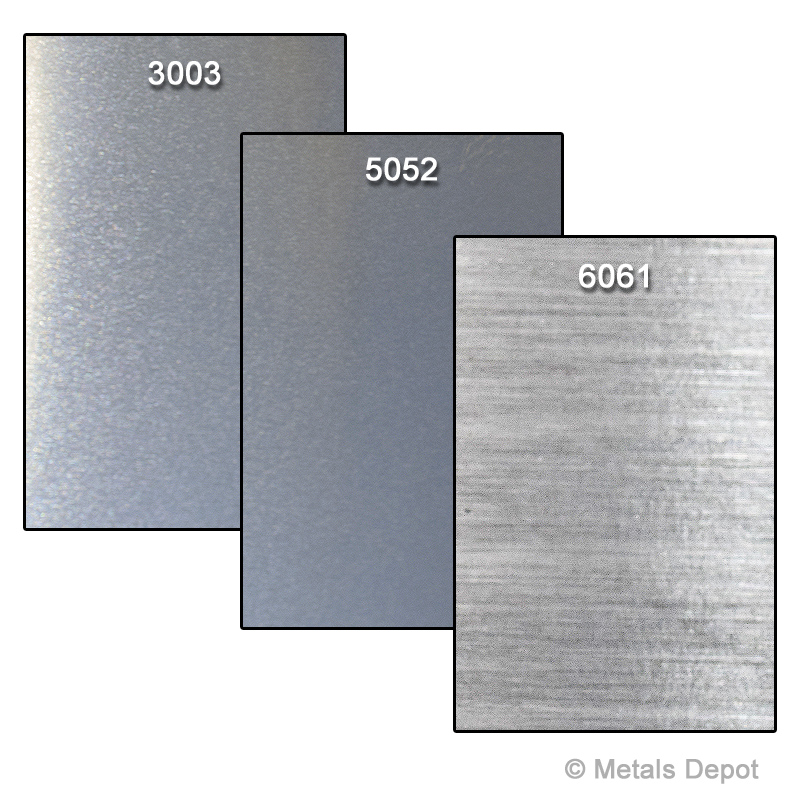

Like steel alloys the aluminum alloy numerical designations distinguish one alloying family and composition from another.

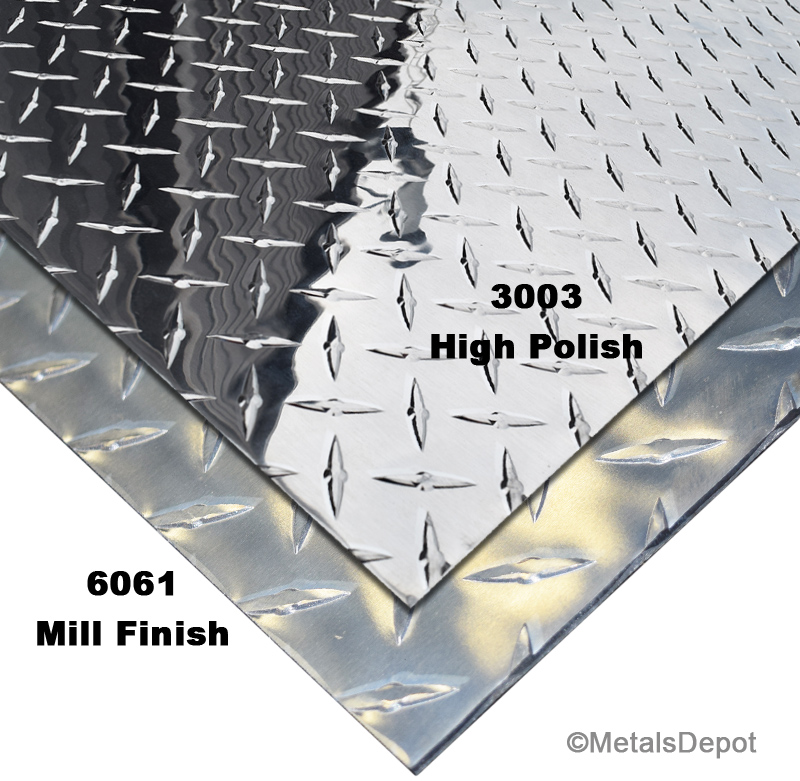

Whether it s an aluminum sheet aluminum plate aluminum bar or aluminum angle 6061 is the choice for a wide range of applications including boats furniture and structural applications.

Amd supply carries an array of 6061 supplies as t is workable weldable and has good cold formidability.

Unlike steel alloys however only the first digit in the grade designation tells you anything about the composition.

All these properties make this a perfect grade for sheets extrusions tubes pylons and for department of transportation related applications.

Aluminum comes in many different shapes and grades.

Your intended use allows you to rank the characteristics of each grade from most important to least important.

The type of aluminum grade you choose ultimately depends on how you intend to use the metal.

Grade 5251 is a medium strength alloy usually supplied in sheet form and is most commonly supplied in temper h22.

6061 is one of the most commonly used grades aluminum grades in the world.

What makes the grade 316 alloy an ideal food grade steel sheet material is the fact that it has a high resistance to acids alkalis and chlorides such as salt.

Other austenitic stainless steels such as grade 304 ss can experience severe pitting corrosion when exposed to salt which is often present in food products.

It has excellent workability.

This will help you narrow down the list of suitable grades.

The use of 2024 aircraft grade aluminum sheet fully meets the performance requirements of aircraft skin.

6061 aluminum alloy is the most flexible of the heat treatable aluminum alloys while maintaining most of the excellent aluminum characteristics.

This grade has a wide range of mechanical properties and resistance to corrosion.